Features:

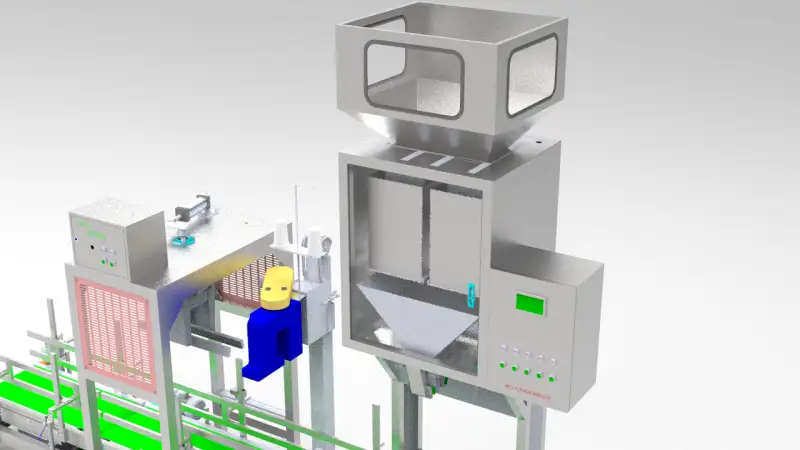

Quantitative packaging scale in industrial or agricultural automatic production of automatic quantitative packaging, all a set of processes are electronic equipment computer control weighing, and then automatically completed. It has the advantages of fast weighing speed, simple and convenient, saving time and manpower. The weighing accuracy of quantitative packaging scale is very high, and it is more convenient to use. In the normal working state, the weighing operation function starts to open the feeding door for batching.

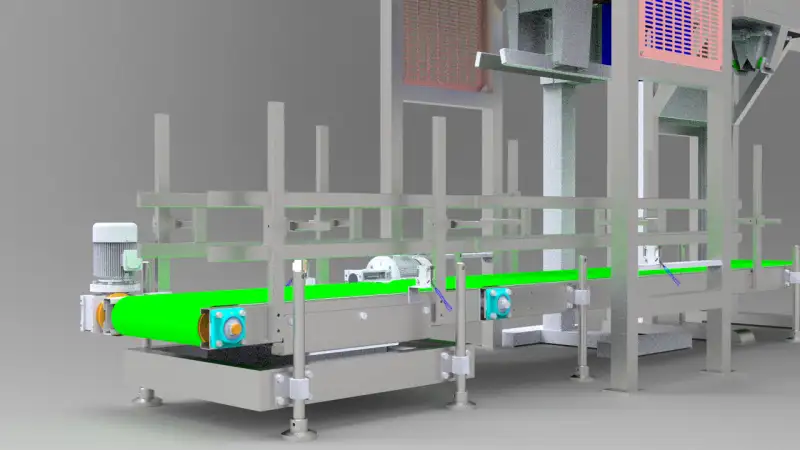

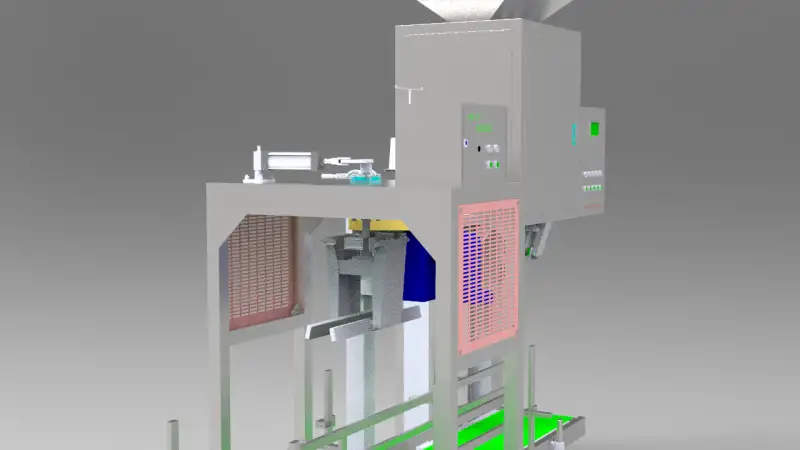

When feeding, it can control slow feeding or fast feeding, and stop feeding. When the batching reaches the standard weight, the feeding door will be closed, which completes the weighing operation. After completion, the system will automatically detect whether the packaging bag is in the predetermined condition. After the bag is clamped, the quantitative packaging scale system will send out the completion signal, and then the ingredients will enter the bag, and the packaging bag will automatically fall down for packaging and transmission to the next department for wake-up processing.

Technical parameters:

- Applicable materials: soybean, corn, rice, etc

- Measurement method: double bucket fan-shaped measurement without damage

- Weighing range: 20kg 60kg

- Measurement accuracy: X (0.2)

- Working temperature: – 40 ° C ~ + 40 ° C

- Weighing speed: 13-15 bags / min 45-54 T / h

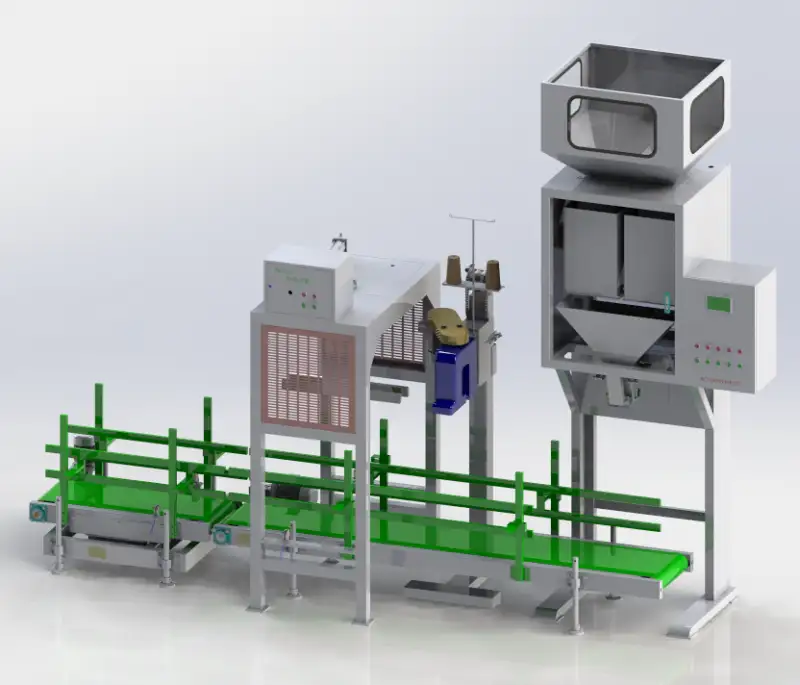

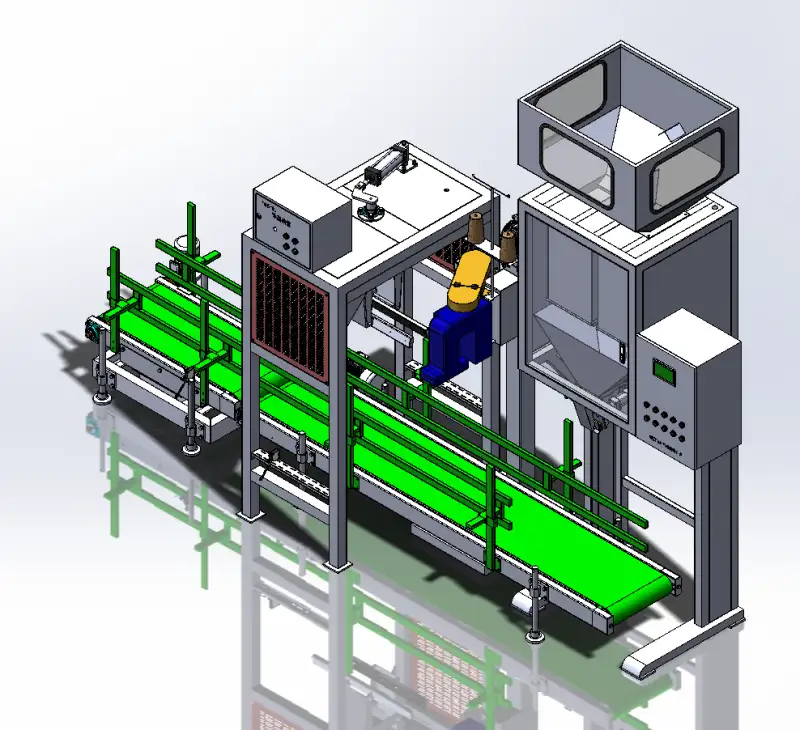

- Overall dimension: 3300x2100x4300 (mm)

- Working voltage: AC380V + 10%

- Power: 1.8kw

New automatic control instrument (anti vibration, anti-interference), high precision positioning stepping motor (fast speed, accurate accuracy, no need to preheat), high precision proximity switch, long life and low power consumption.

This 3D model designed by SolidWorks 2017, detailed design including every part like pictures below, step and 2D files included for you. The file total of 81 MB.