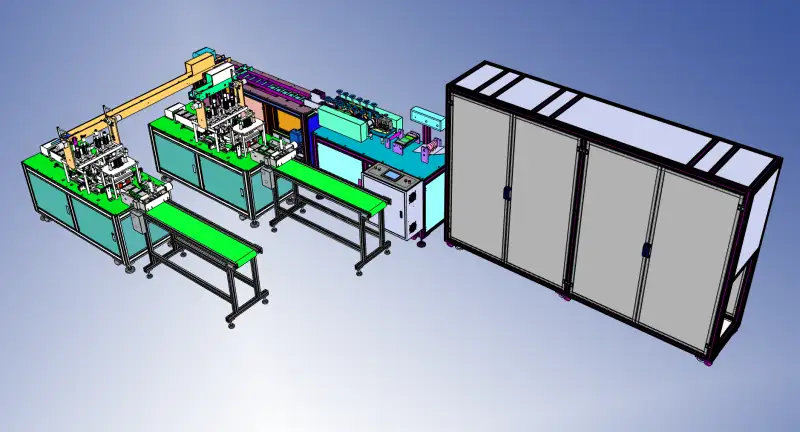

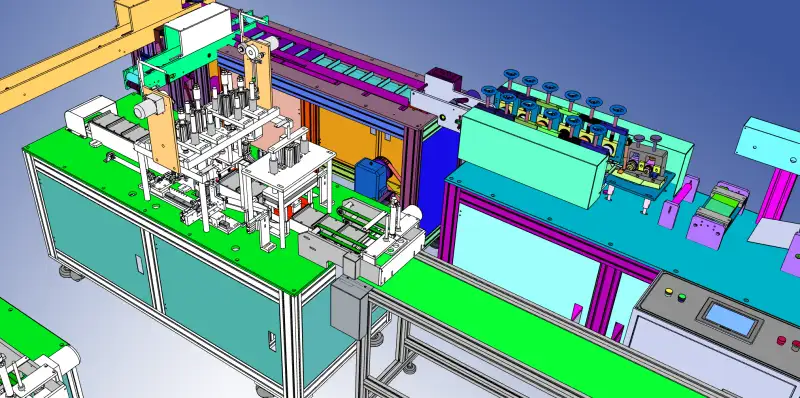

SolidWorks 2018 3D model of automatic mask machine, including STP files for you open in other 3D software. The files total 253 MB. Please use ABOVE 2018 edition of SolidWorks, lower edition cannot open this model.

Equipment overview:

Disposable three-layer mask is made of two layers of non-woven fabric and filter paper which is professionally used for medical treatment. Over 99% of the filter sprays are made by ultrasonic welding. The environmentally friendly plastic strip is used at the bridge of the nose. It does not contain any metal. It is equipped with vapor permeability and is comfortable. The filtering effect is up to 99%.

Technical parameter:

Raw materials: 2 layers of non-woven fabric (weight about 25g), PP non-woven composite fiber;

The middle layer is melt blown cloth;

Nose bridge wire plastic strip PP 5.0 mm * 0.55mrr;

Ear band is round with a diameter of 2.5-3 mm;

Finished mask specifications: adult 175 * 95 mm and child 95 * 140 mm (standard 1 optional)

Production speed: about 100 PCs / min

Equipment composition: mask machine body (1 unit), mask connection line (1 unit) and mask outer ear strap machine (2 units) form a one-to-two fully automatic disposable three-layer mask machine production line.

Special note:

Other configurations required for medical grade masks (not included in this device):

1. Use medical grade materials;

2. With GMP production dust-free workshop;

3. The masks are packed in outer bags according to the number of packages;

4. Equipped with medical-grade sterilization equipment.