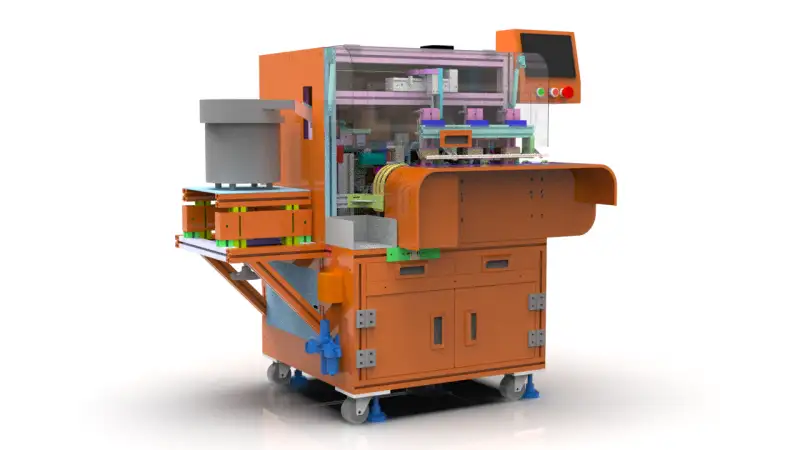

3D Modeling of Automated Earphone Jack and Headphone Cable Soldering Equipment

The 3D modeling of automated earphone jack and headphone cable soldering equipment is an innovative solution that streamlines the manufacturing process of earphones by automating the intricate task of soldering the plug and cable. This cutting-edge equipment employs advanced technologies and precise engineering to ensure efficient and consistent production.

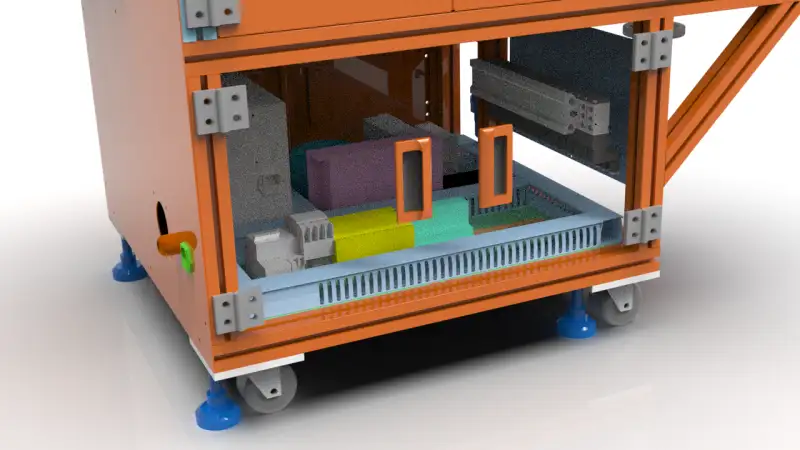

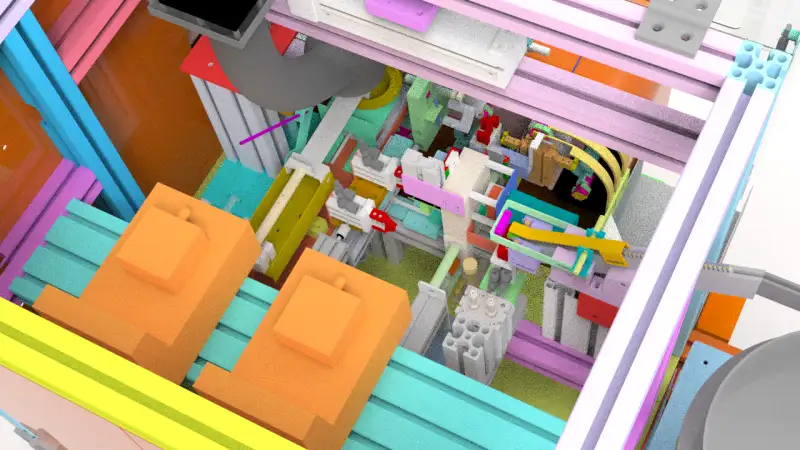

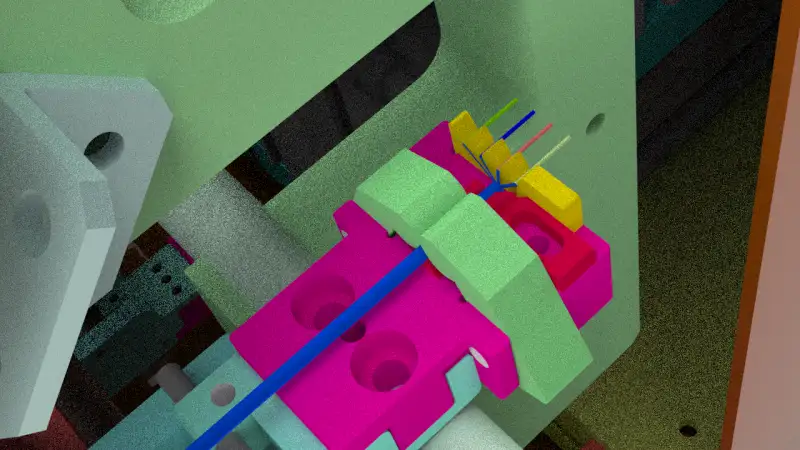

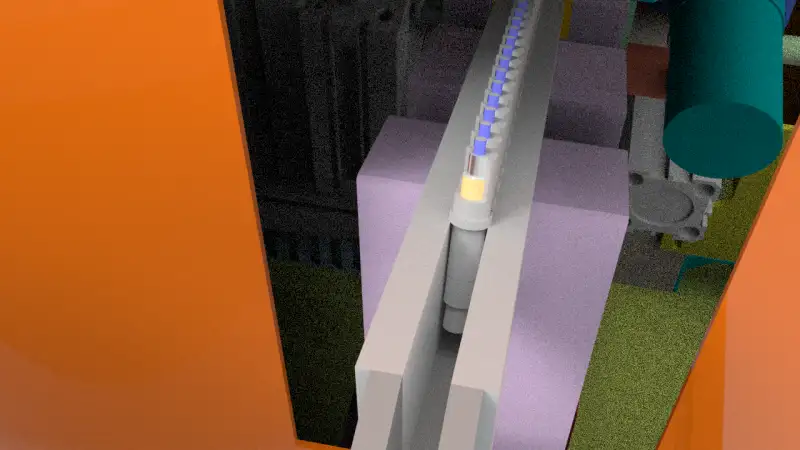

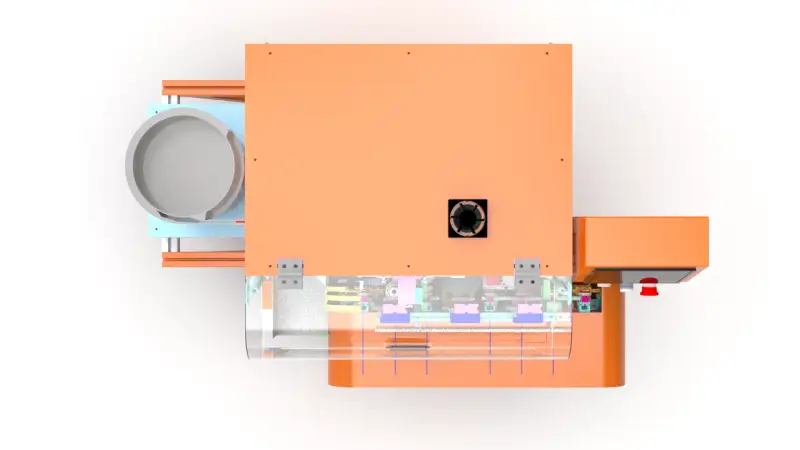

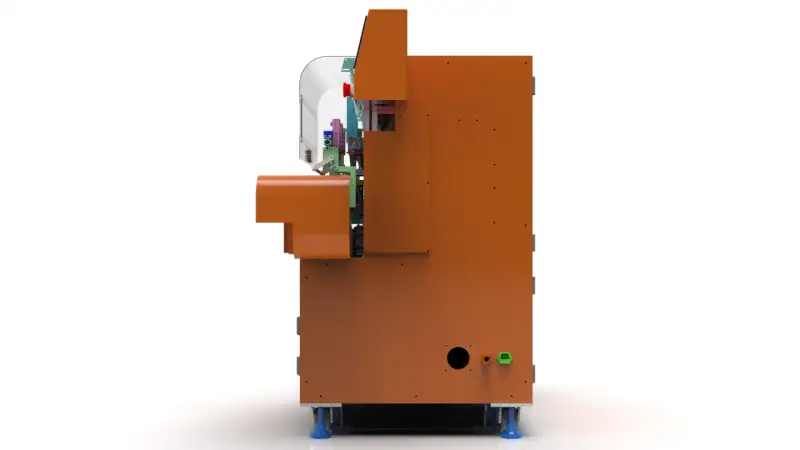

The three-dimensional (3D) model design of this automated equipment incorporates the detailed structures and functionalities required for seamless integration into production lines. The equipment comprises a robotic arm, soldering tools, and a control system, all meticulously designed to facilitate accurate and reliable soldering.

The 3D model offers a realistic representation of the machinery, allowing manufacturers to visualize and optimize their production setups. It enables engineers to assess potential concerns and make necessary adjustments before the physical prototypes are created. This virtual representation significantly reduces both time and cost in the design and testing phases of the equipment.

The automated soldering equipment is designed to accommodate various earphone jack and headphone cable types, ensuring versatility and compatibility across different product models. It utilizes specialized algorithms and sensors to precisely position and secure the jack and cable, guaranteeing high-quality soldering connections.

By automating the soldering process, this equipment enhances productivity and reduces errors that may occur during manual soldering. It provides a consistent soldering quality, resulting in improved overall product performance and reliability.

This 3D design was created using SolidWorks 2020. The file size is 149 MB, which includes a step file that can be opened in other 3D software.