The automatic sorting system can identify the barcode of the waybill, and sort the parcels quickly and accurately according to the user-defined chute. It has the characteristics of high site utilization, high sorting efficiency, and low error rate. It is widely used in the express delivery and e-commerce industries, which can reduce the manpower by 40-70%.

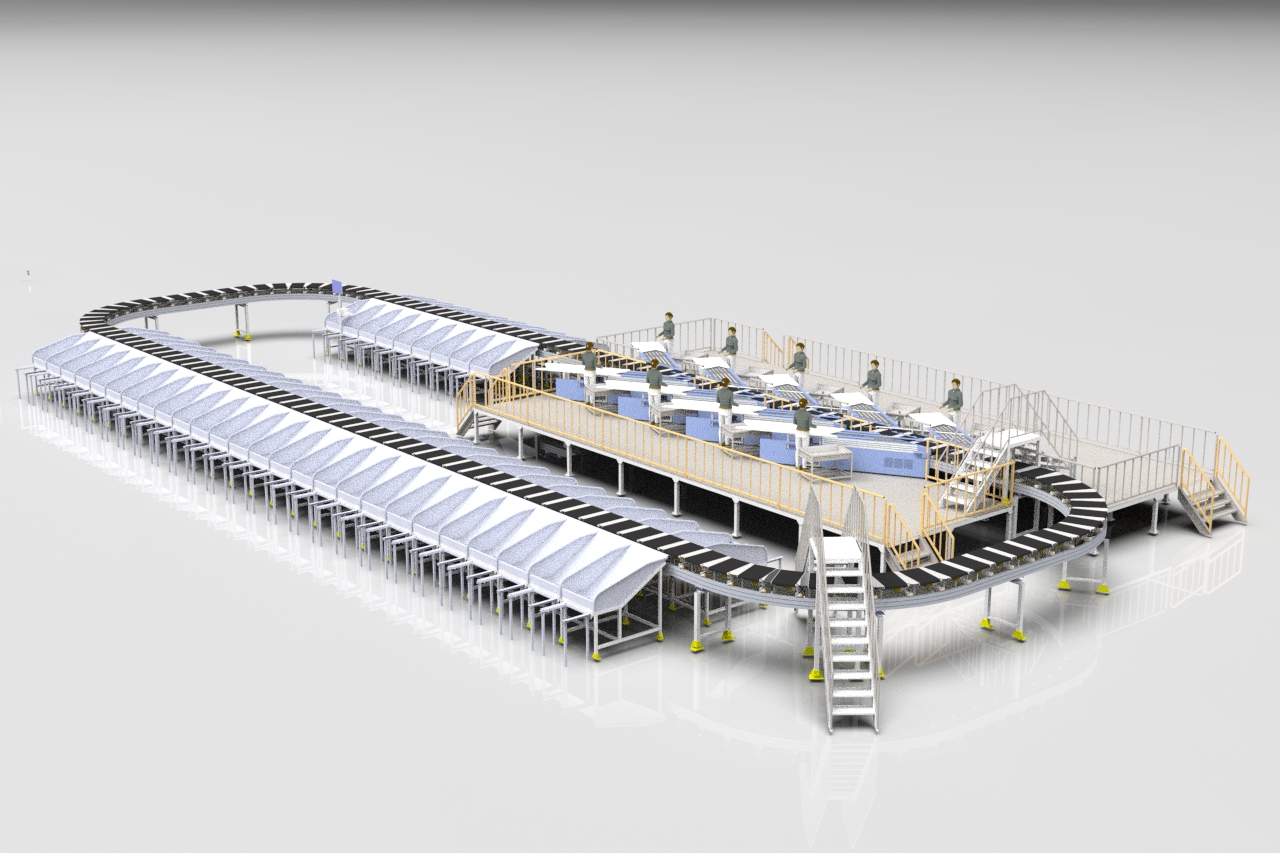

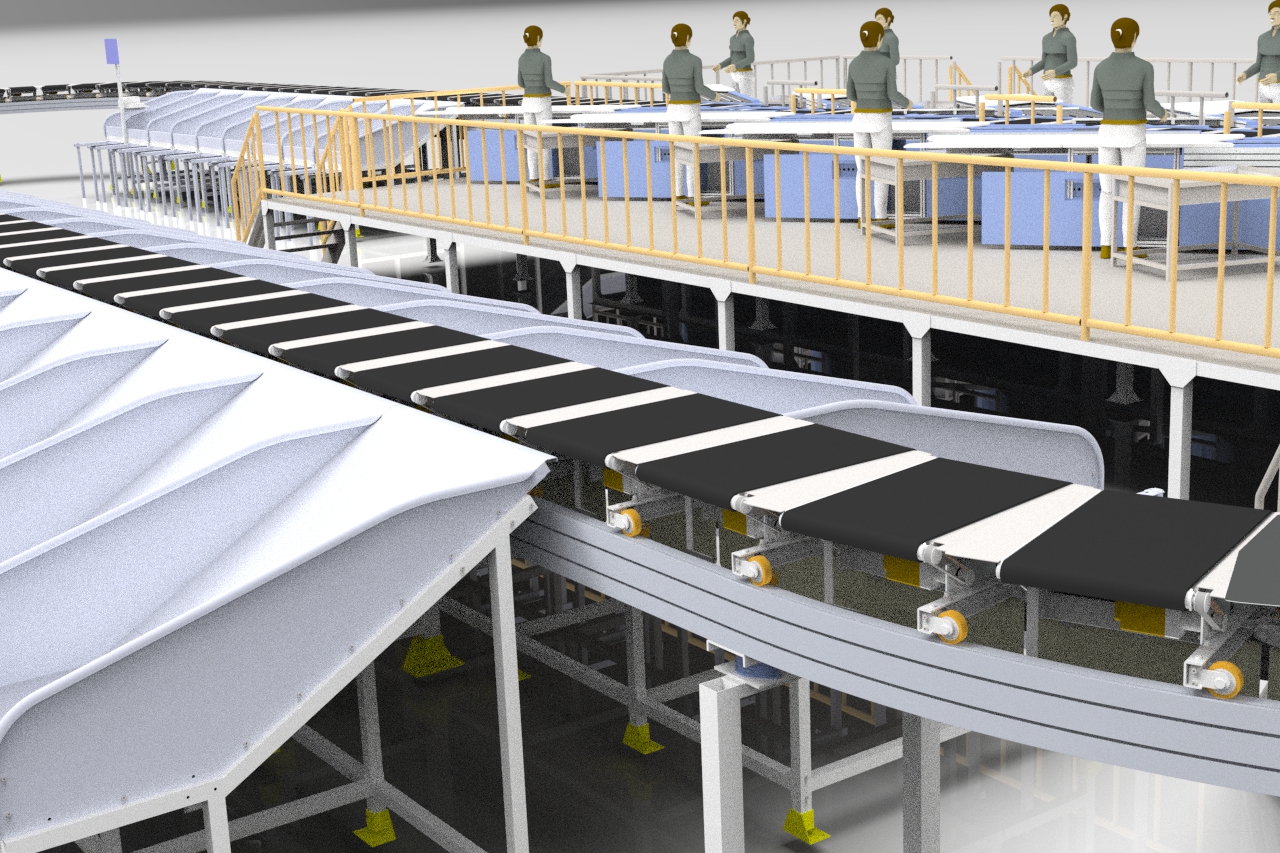

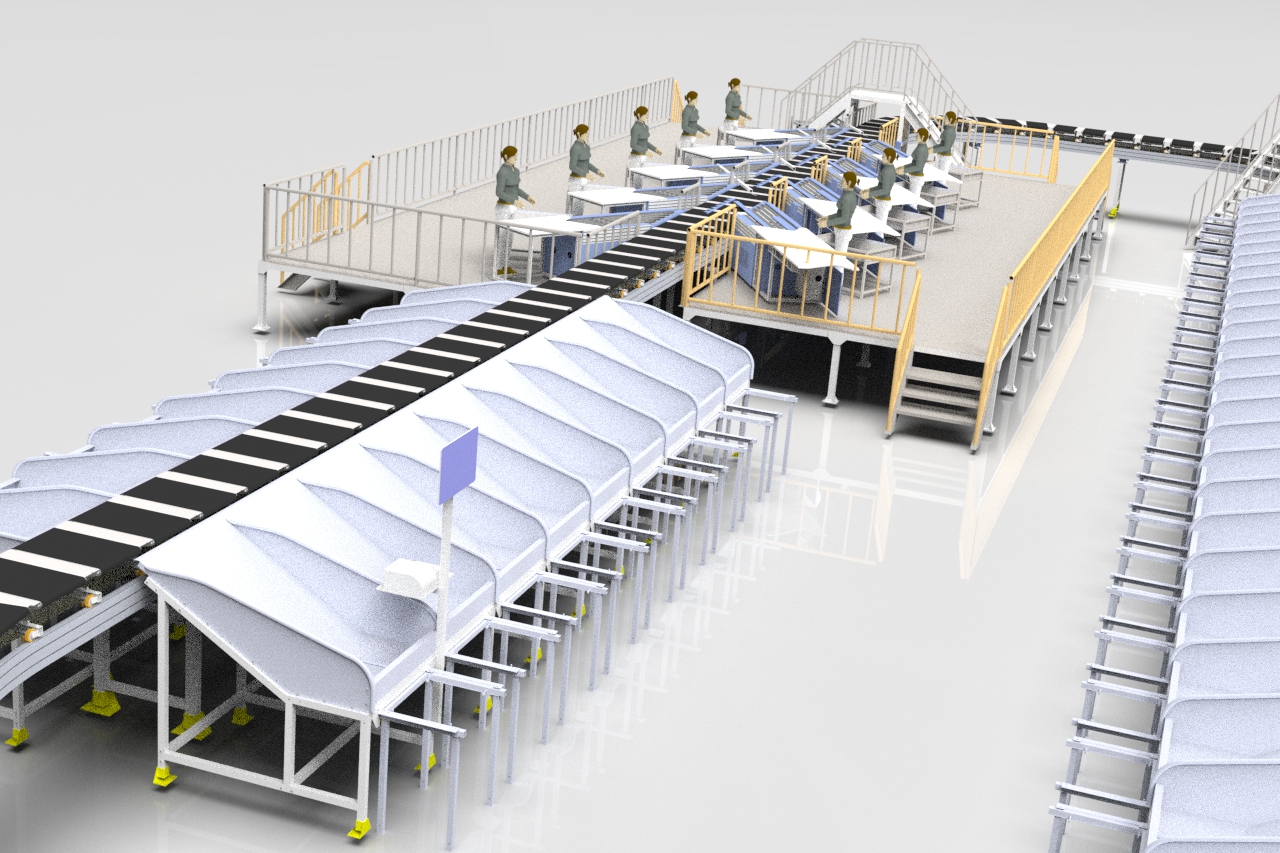

“It is mainly composed of trolley, rail, lead-in system, code scanning system, sorting grid, reflux device, etc.

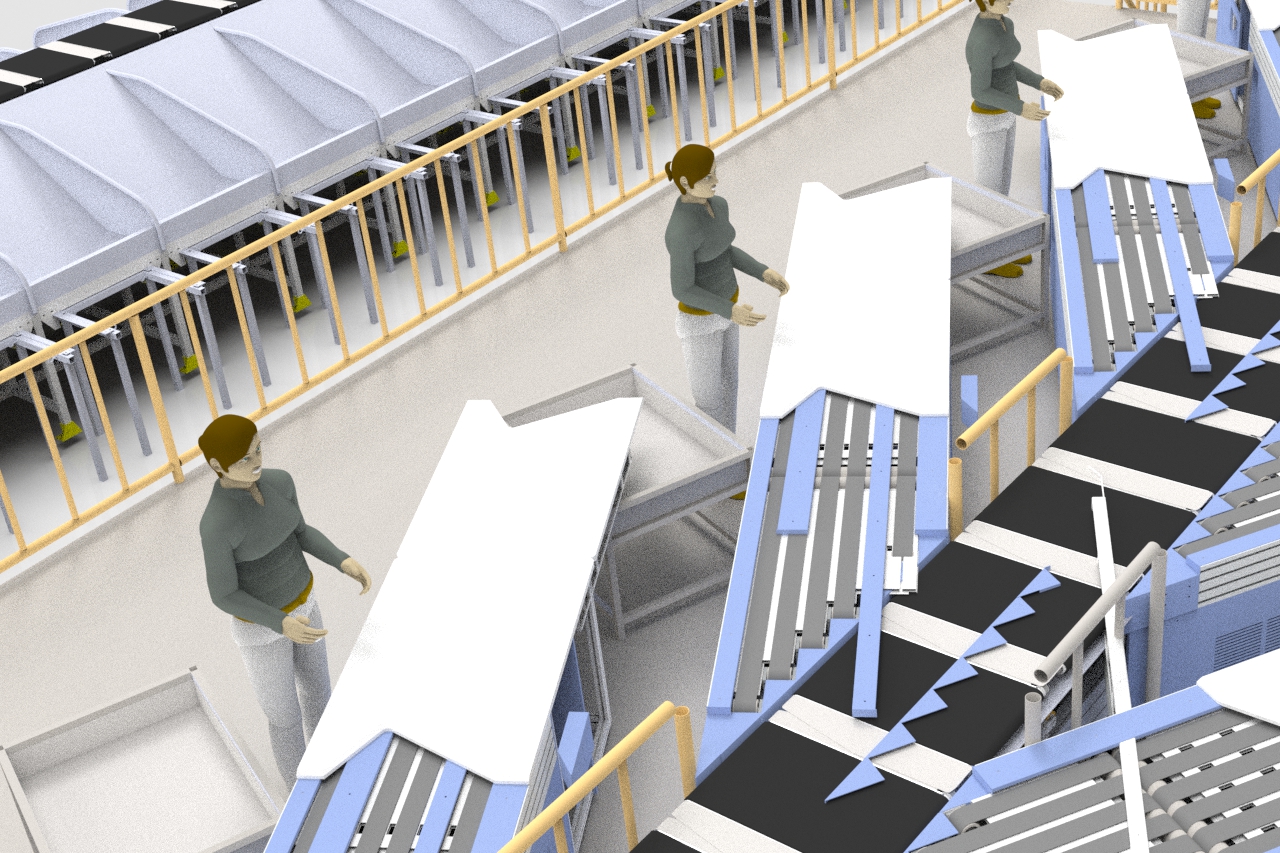

The working principle is a closed conveying and sorting system composed of a group of trolleys. The trolley moves along the track in a loop, and the surface belt of the trolley unloads in a direction perpendicular to the loop. The package is accurately transported to the trolley via the induction table. After being scanned by the barcode system, the barcode (barcode or QR code, etc.) posted on the package is identified, and the packages with different destinations are unloaded at different outlets according to the barcode information. ”

This 3D designed by SolidWorks2020, the file totally 138 MB, including step file for other 3D software open.