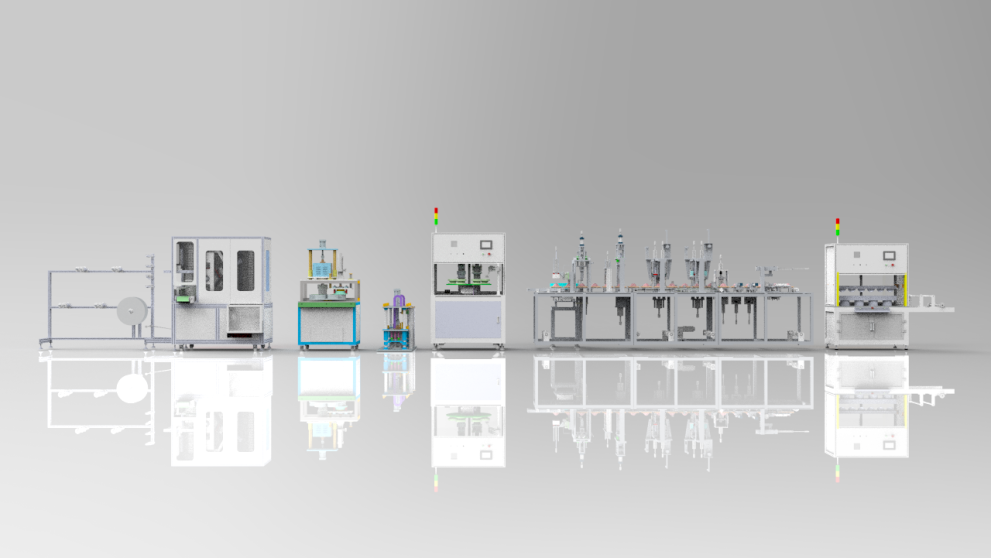

Cup mask machine is composed of a series of machines for producing cup masks, including: Cup mask forming machine, cup mask machine, rotary cup mask welding slicer, cup mask breathing valve punching machine, cup mask nose line bonding machine, cup mask ear belt spot welding machine, cup mask monochrome pad printing machine, cup mask breathing valve welding machine, etc.

This 3D model designed by SolidWorks 2018, detailed design including every part like pictures below, step files, 2D drawing of SolidWorks2018 files? included for you. The file total of 511MB.

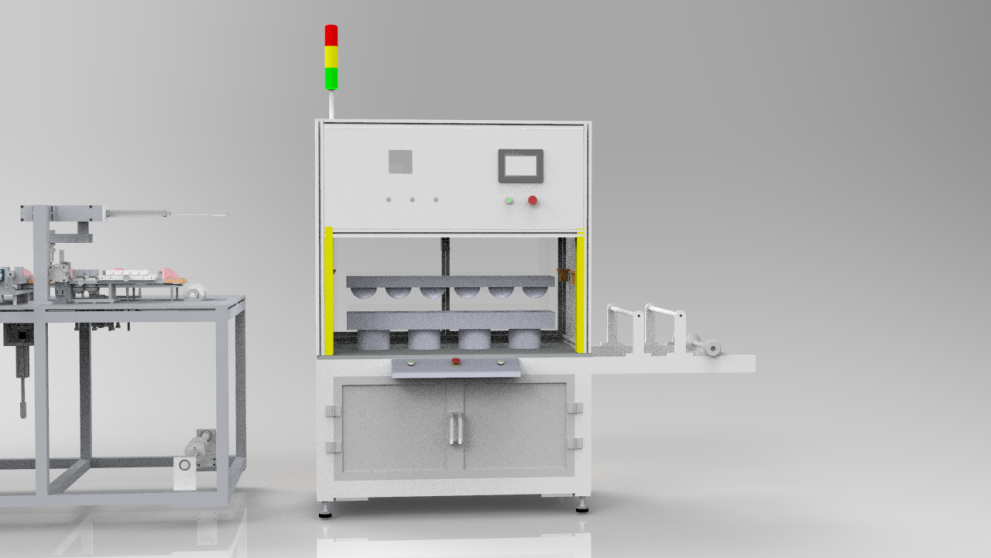

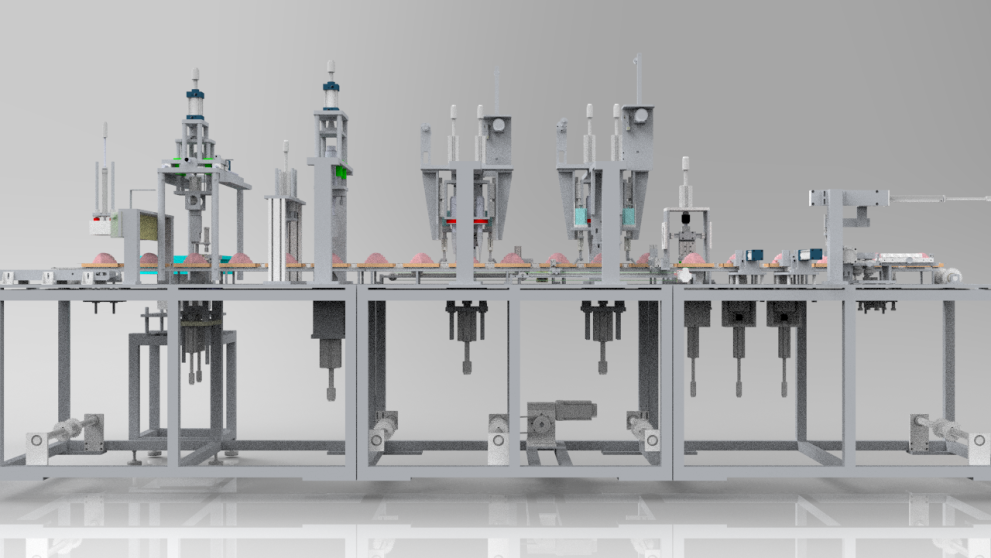

Cup mask forming machine

The cup mask forming machine can automatically complete multiple processes from feeding to one-time forming, shearing and returning. Compared with the traditional manual feeding, returning and shearing, 3-5 labor can be saved, and 30-36 masks can be produced per minute. PLC control system and touch screen setting are adopted. The operation is simple and fast. It can be used by a single person, and only manual feeding and reclaiming are needed. It greatly improves the production efficiency.

Parameters of automatic cup mask forming machine:

Air pressure: 5kg / cm2

Machine size: 3400 * 1230 * 1900mm

Machine weight: 500kg

Maximum power: 10kW;

Working power: 5KW

Speed: 30-36pcs / min

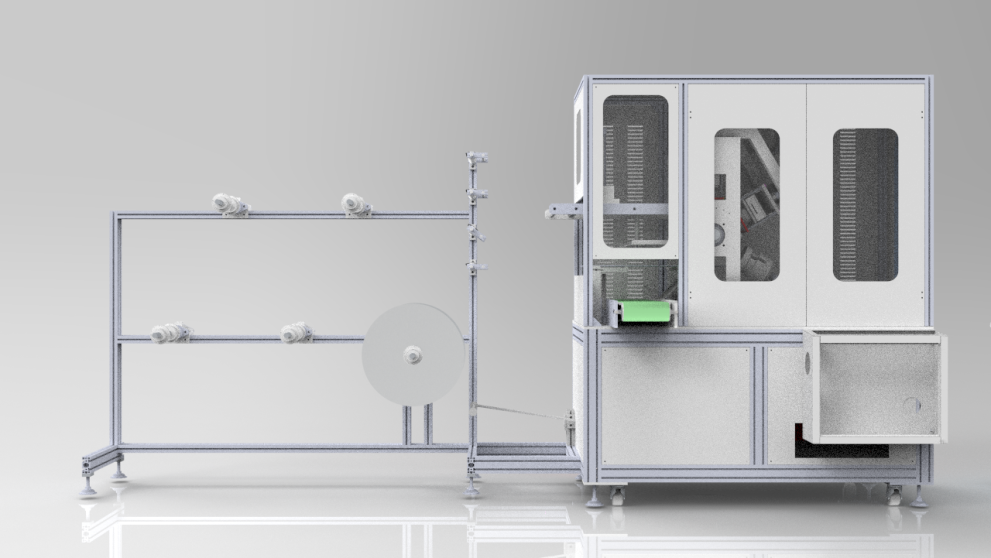

Cup mask machine

Cup mask machine, also known as slicer, mainly uses the principle of ultrasonic cutting and automatic welding edge sealing to complete the irregular cutting and welding of slices. The machine solves the problems of traditional lace machine such as inaccurate positioning, inaccurate size control, low production efficiency and high labor cost. It integrates many processes such as discharging, roller drawing, ultrasonic cutting, waste separation, finished product slicing, which greatly improves the production efficiency, reduces the production cost, and makes the product more standardized, more stable in quality and more beautiful in appearance.

Parameters of automatic cup mask machine:

Power supply voltage: 220 V, 50 / 60 Hz

Machine size: 840x630x1430mm

Weight: 450kg

Size of discharging rack: 1550x620x1510mm

Air pressure: 6kg / cm

Output: 50-60pcs / min

Power: 1800W

Frequency: 20KHz

Features of automatic cup mask machine:

1. Automatic counting, effective control of production efficiency and progress.

2. Frequency conversion control, adjust the running speed of the equipment according to the actual needs.

3. Rotary control box, adjust the direction of the control box according to customer requirements.

4. Automatic collection of waste materials, so that waste materials automatically exit, to reduce manual labor for operators.

5. Pull the barrel to feed, more accurate positioning, can control the width of raw materials to the minimum, save the cost.

6. The length and size of the finished product are controlled uniformly with a deviation of ± 1 mm, which can effectively control the length of the finished product, so that the chip can meet the requirements of the production process and eliminate waste.

7. Independent feeding rack, easy to take and adjust raw materials.

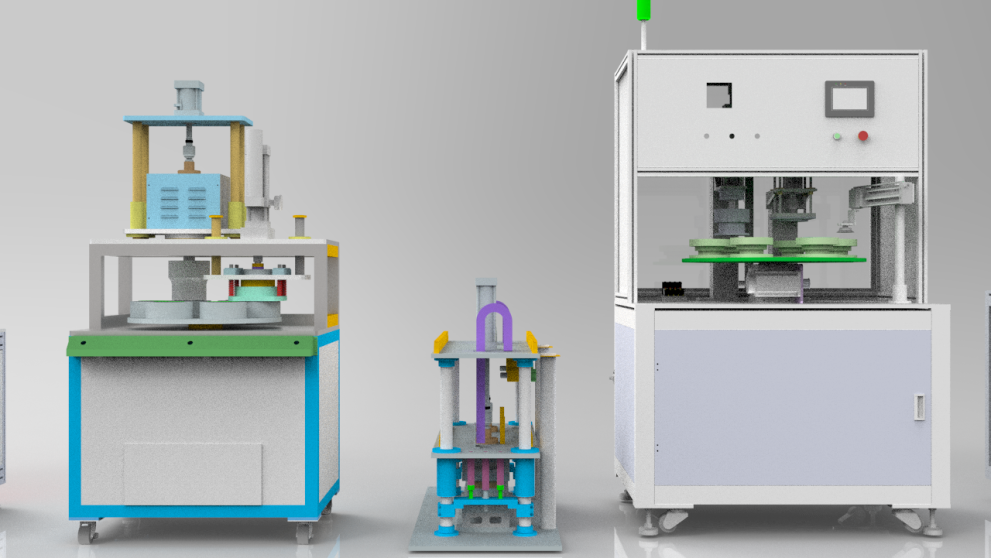

Rotary cup mask welding slicer

Rotary cup mask edge welding and punching machine is a machine which uses the principle of ultrasonic welding and automatic edge sealing to complete the welding and punching process of cup mask edge. This machine creatively combines the two previously independent processes of cup-shaped mask edge melting and punching, multi station turntable, welding with cutting device, welding and cutting two heads work at the same time, PLC control system and touch screen setting are adopted, the operation is simple and convenient, it can be used by a single person, only workers need to put and take materials, which can greatly save labor and make the cup more comfortable The production of the mask is simpler and faster.

Features of rotary cup mask welding slicer:

1. Automatic leveling device, the machine automatically adjusts the level, greatly simplifies the difficulty of use, and ensures the punching effect.

2. Multi position turntable structure, safer operation, can effectively reduce the occurrence of industrial accidents.

3. Welding and trimming are completed on the same machine, with more accurate positioning, more uniform trimming and more beautiful appearance.

4. Gantry structure, so that the whole frame can withstand the greater impact in the punching process, and the punching effect is better

Parameters of rotary cup mask welding slicer:

Power supply voltage: 220 V, 50 / 60 Hz

Product size: 800x1120x1750mm

Weight: 300kg

Power: 4200W

Air pressure: 6kg / cm

Output: 8-10 pieces / min

Punching machine for breathing valve of cup mask

Equipment usage: It is used for punching the front breathing valve of the cup type mask. The pedal switch is adopted. The operation is simple. The punching size and the mask mold can be designed according to the customer’s needs. It is an ideal punching equipment for the production of masks with breathing valve.

Machine features:

1. Accurate punching

2. Fast, 50-60 per minute

3. Easy to operate

4. Quiet and noiseless

5. The machine is small and does not occupy space

Automatic cup mask machine

Equipment parameters:

Power: 5KW

Voltage: 220 V

Weight: 500kg

Dimensions 3500 x 1500 x 1800mm

Efficiency: 20-70 / PCS

Air pressure: 5kg / cm2

Features of automatic cup mask machine:

1. The advanced servo and constant temperature control system adopts PLC program control to complete the material from entering to forming, welding to punching at one time, and the whole production process is fully automatic.

2. The equipment only needs to be equipped with a full-automatic welding machine for the nose and ear strips of cup masks, and numerous cup masks can be produced in the market.

3. The products are exquisitely made, and the quality completely meets or exceeds the testing standards at home and abroad. At the same time, it can save more than 30% material than the mask equipment in the previous market. Thus the real sense of the realization of the cost reduction, improve efficiency!

Spot welding machine for ear band of cup mask

Mechanical parameters:

Air pressure: 3kg / cm

Power: 500W

Frequency: 35K

Voltage: 220 V

Machine size: 800 * 600 * 1400mm

Capacity: 10-12 tablets / min

Machine performance:

1. The design of the machine is small and flexible, and the operation is simple and convenient.

2. It can be used for welding plane, inner / outer ear band, cup mask, duck mouth mask and other special-shaped masks.

3. After the mask body is made, the ear band is welded manually, which is easy to operate and the contact is firm and beautiful. Skilled workers weld 10-12 pieces per minute.

characteristic:

1. The ultrasonic spot welding machine adopts the original transducer, with stable output, high-quality component assembly, reliable performance, dexterous design and convenient operation. It is mainly suitable for N95 mask (cup mask, dust mask, duck mouth mask, plane mask, etc.) ear belt spot welding design, with high production efficiency, simple operation and stable quality;

2. The double guide pillar design can solve the problem of backward during welding;

3. The operation is simple, the welding spot is firm and beautiful after welding, and the material itself is not damaged.