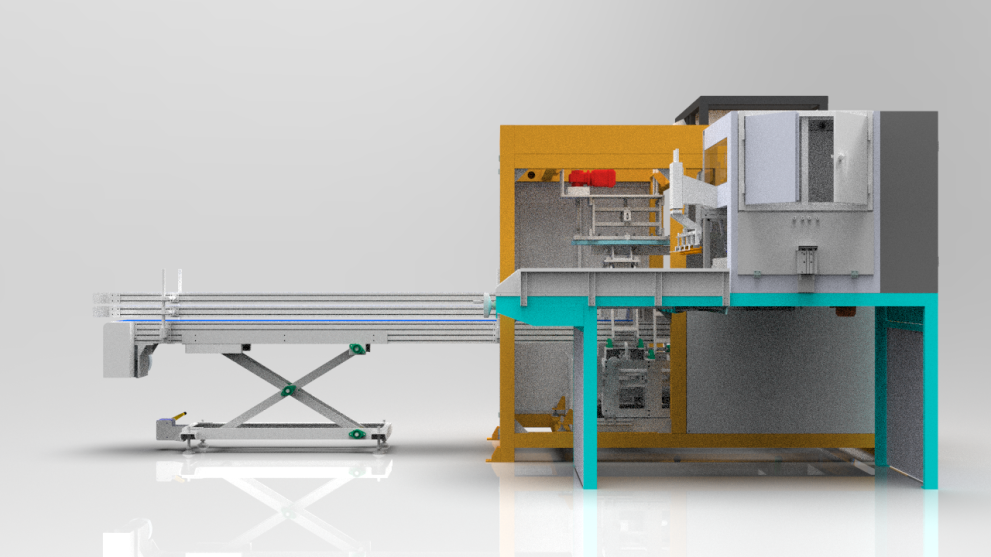

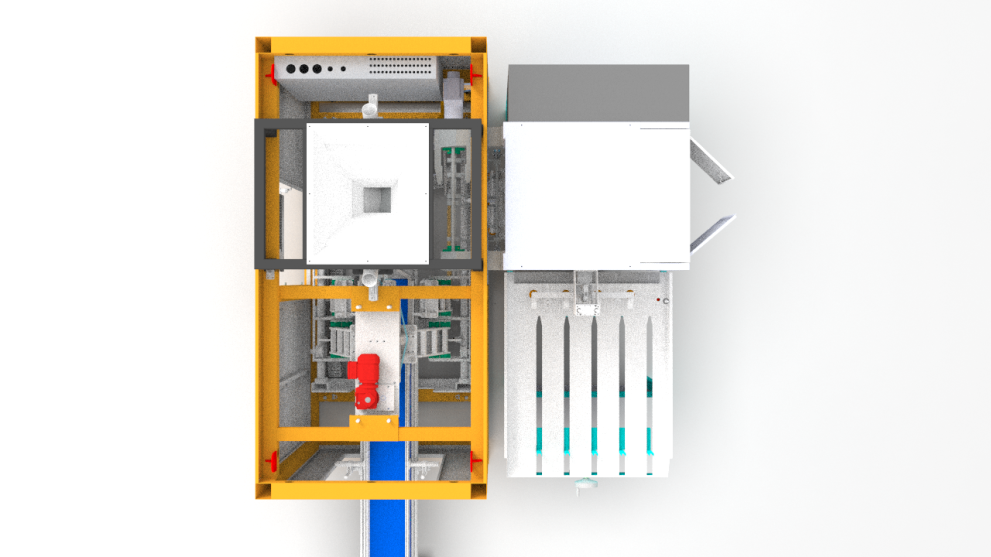

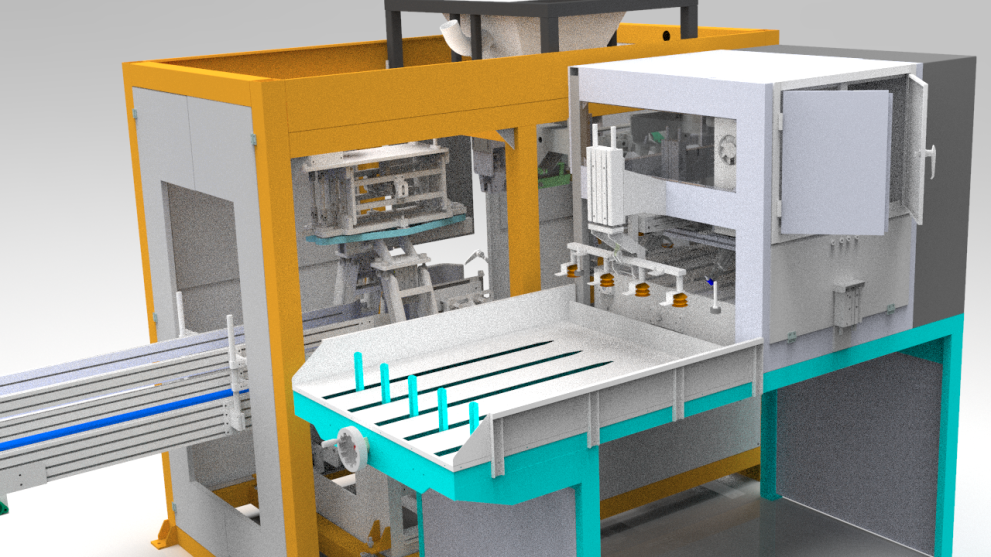

A fully automatic packaging equipment. The system integrates the functions of automatic bag loading, automatic label / certificate, automatic edge folding and automatic sewing, and can realize the automatic and unmanned packaging process of bagged materials. The equipment mainly includes: automatic quantitative scale (optional), automatic bag loading device, automatic bag warehouse, bag moving mechanism, bag guiding mechanism, automatic folding / sewing machine, automatic labeling machine (optional), finished product conveyor, etc. It mainly completes the automatic packaging process of automatic weighing, automatic bag loading, automatic filling, automatic folding and sealing.

Working process:

Place the packaging bag in the bag warehouse → place the label in the label box → start the machine to run → the bag taking mechanism automatically sucks the packaging bag → straightening and conveying → opening the bag → supporting the bag → bagging (loading the bag) → filling the material → loosening the bag / holding the bag / moving the bag → labeling / folding / sewing → entering the next process (palletizing, etc.).

Equipment features:

1. Low requirements for packaging materials: non breathable, non thermal cut woven bags, plastic bags, paper bags, non-woven bags, soft bags and hard bags.

2. The requirements for the uniformity of the placement position of the packaging bags are low: the allowable error of the accuracy in the length direction is 5-8cm, and the allowable error of the accuracy in the width direction is 3-5cm.

3. It can adapt to multi specification packaging bag: length range: 700cm-110cm, width range: 45cm-65cm.

4. The unique and reliable detection technology can completely prevent the materials from falling to the ground: the unique and reliable detection technology can ensure that the packaging bags are in place for detection, and prevent the materials from falling to the ground due to the packaging bags are not in place.

5. Perfect and practical detection and alarm reminder function: it has no packaging bag, no label, broken wire, broken needle, jumper and other detection and alarm reminder functions.

6. Fault location function: in case of equipment fault alarm, the man-machine interface will prompt the fault point at the same time, which can guide the operator to quickly diagnose and deal with it.

7. Manual auxiliary bagging function: “manual auxiliary bagging function” can be used for emergency discharge to meet the special process requirements of handling head and tail materials.

8. Remote diagnosis and maintenance function (optional): it can diagnose and maintain the use of field equipment remotely, and guide field personnel to quickly and accurately remove faults.

Power supply voltage (V / Hz)(V/HZ):AC380/50

Total power:3.5kw

Air pressure:0.5-0.7mpa

Gas consumption:750nl/min

Overall dimension (L * w * h):4000mm*2800mm*2400mm

Packaging speed:400-500 bags / h, 500-650 bags / h

Net weight:2300kg

Packaging scope:20-50kg bagged products

Material of packing bag:Paper bag, airtight woven bag (non thermal cut)

This 3D model designed by SolidWorks 2017, detailed design like pictures below, step files included for you. The file total of 220 MB.