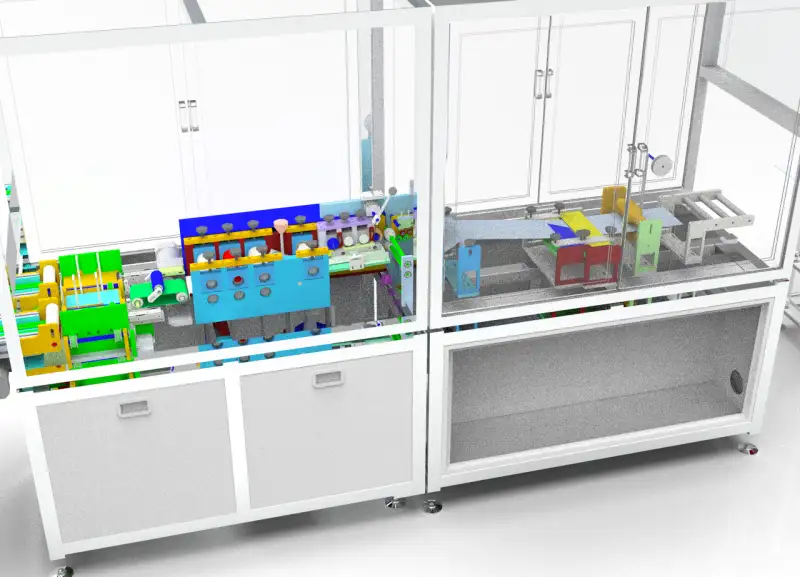

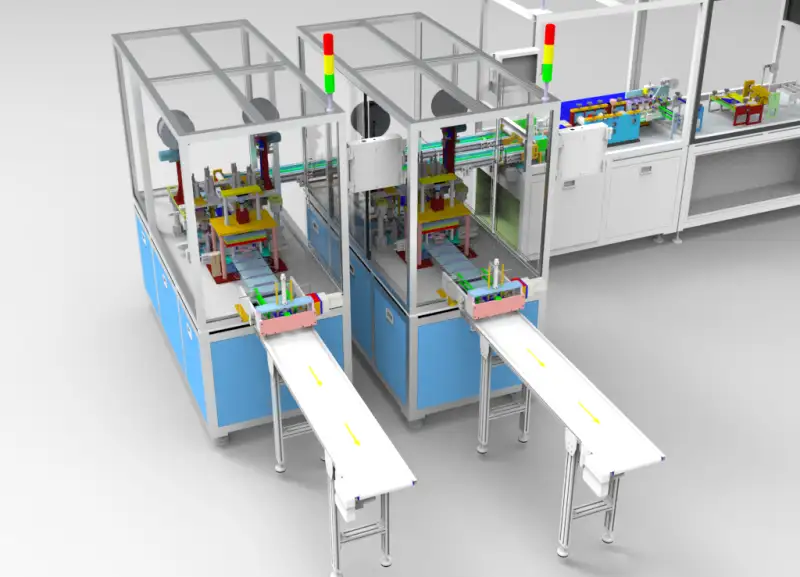

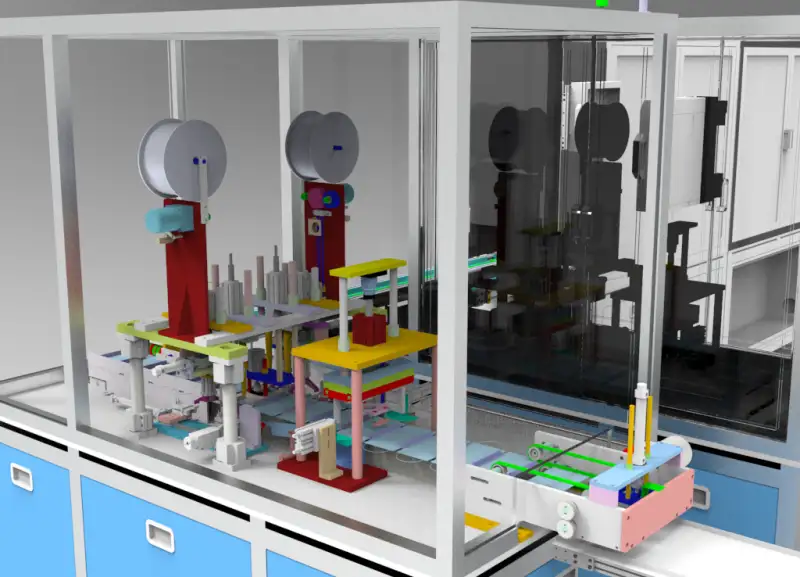

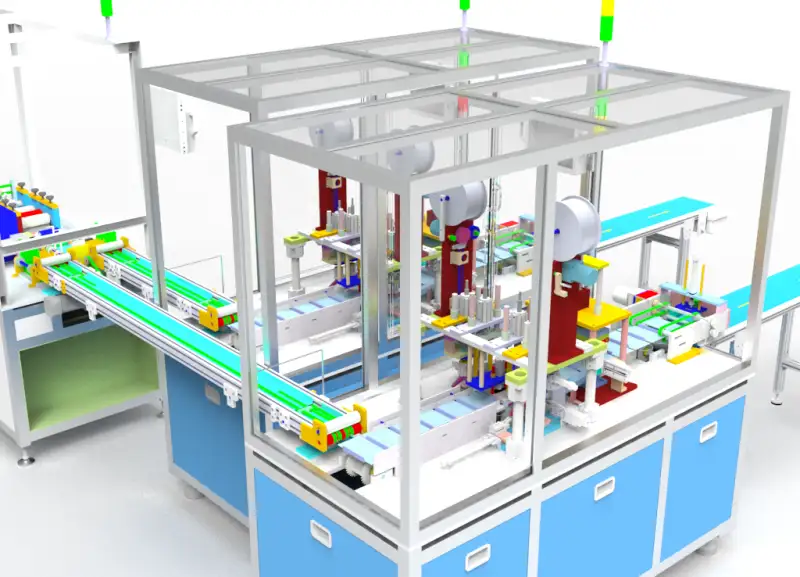

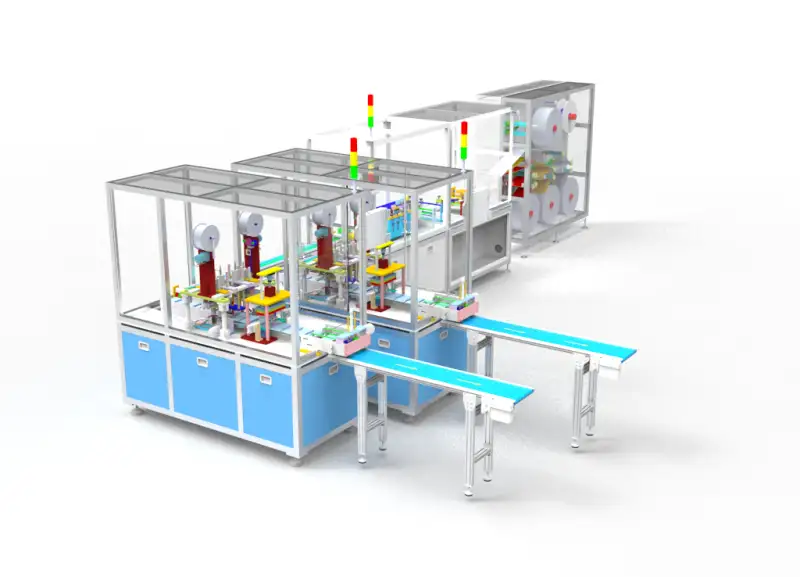

This 3D model is a 1-2 face mask making machine with safety covers, the covers in the production lines mainly for safety. The model can be opened by Solidworks 2017, and stp file is provided. File size total 200MB.

The model can provide you some learning refferences during your automation product lines design process, it will help you save a lot of time.

Equipment overview:

Disposable three-layer mask is made of two layers of non-woven fabric and filter paper which is professionally used for medical treatment. Over 99% of the filter sprays are made by ultrasonic welding. The environmentally friendly plastic strip is used at the bridge of the nose. It does not contain any metal. It is equipped with vapor permeability and is comfortable. The filtering effect is up to 99%.

Technical parameter:

Raw materials: 2 layers of non-woven fabric (weight about 25g), PP non-woven composite fiber;

The middle layer is meltblown cloth;

Nose bridge wire plastic strip PP 5.0mm * 0.55mrr;

Earband is round with a diameter of 2.5-3mm;

Finished mask specifications: adult 175 * 95mm and child 95 * 140mm (standard 1 optional)

Production speed: about 100 pcs / min

Equipment composition: mask machine body (1 unit), mask connection line (1 unit) and mask outer ear strap machine (2 units) form a one-to-two fully automatic disposable three-layer mask machine production line.