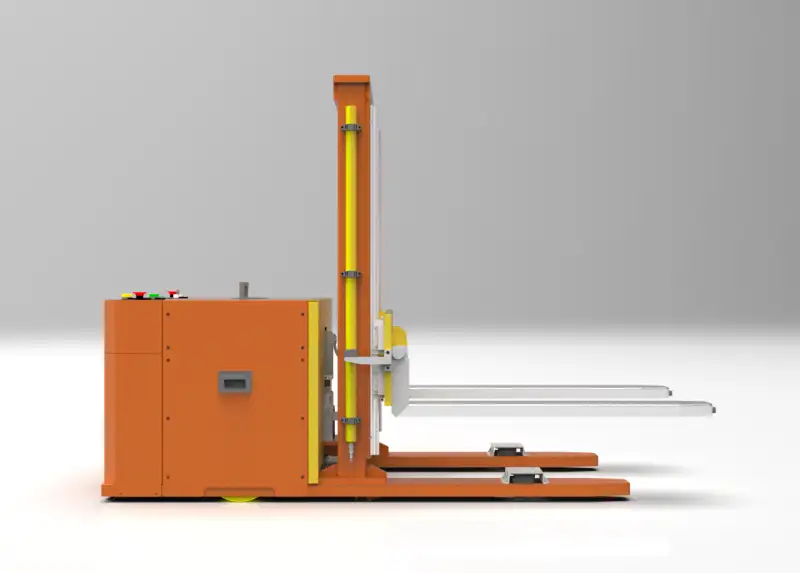

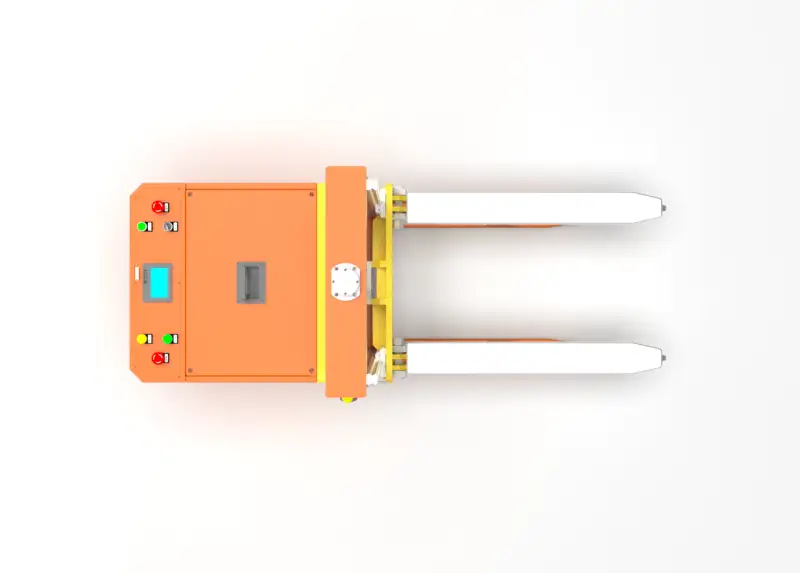

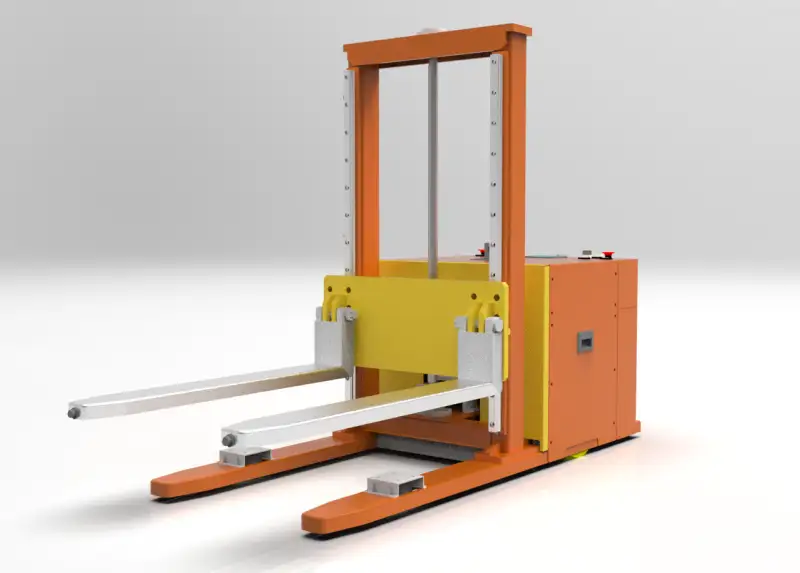

It is composed of hydraulic lifting system, differential drive system, PLC control system, guidance system, communication system, warning system, operation system and power supply.

It is a programmable wireless scheduling automatic guidance car with hydraulic lifting and PLC control; Electromagnetic induction is used as navigation mode to assist RFID identification, which can run in complex path and multi site reliable tracking;

The main drive is driven by a self-developed differential servo motor and equipped with a high-precision angle steering actuator, which makes the whole vehicle respond quickly and locate accurately;

The independent hydraulic lifting system assisted with high-precision displacement sensor enables the forklift to stop at any position within its lifting stroke, greatly improving the loading flexibility and lifting position accuracy.

Based on the reflector laser navigation technology (more stable than other navigation technologies such as vision), it can obtain the position of forklift in the environment. After receiving the handling task, it can automatically complete the operation of driving, handling, stacking, charging, etc., without manual participation in the whole process, helping customers reduce costs and increase efficiency.

The unmanned forklift can run flexibly and change the driving route at any time, and its navigation accuracy can reach 100% ± 4mm, meeting most of the transport scenarios. At the same time, it also has advanced and complete safety protection system to avoid collision with obstacles, ensure vehicle stability, and ensure the safety of personnel and goods.

1. Drive system: the independently developed differential drive configuration, high-precision angle steering control is the driving and steering guarantee of the whole vehicle, and the efficient AC servo motor drive ensures fast motion response, stable start and stop, accurate positioning and long service life;

2. Control system: the vehicle mounted independent control box is integrated with industrial PLC central control, which greatly improves the operation speed, stability and anti-interference ability of the system compared with the circuit board control, and simplifies the programming and path planning;

3. Lifting system: PLC control and independent hydraulic lifting system are equipped with high-precision displacement sensor, so that the forklift arm can start and stop accurately at any position, and the operation height can be set simply through the program, which greatly improves the accuracy and flexibility of loading height;

4. Communication system: PLC control is equipped with wireless communication module and handheld remote control operation box, which can easily realize remote dispatching, wireless communication, traffic management and manual remote control, and ensure the real-time and reliability of information exchange;

5. Guidance system: electromagnetic induction, laser navigation and image recognition guidance are optional, with high guidance precision and good controllability; For the tracks with complex paths and more sites, RFID is equipped to identify the sites reliably to ensure the most reasonable path planning and free deployment of multiple sites;

6. Obstacle avoidance system: laser, photoelectric, infrared, ultrasonic and other multiple obstacle avoidance methods can be selected, plus the inherent mechanical collision sensor of the body to form an all-round obstacle avoidance protection net, which can effectively avoid various potential dangers in the movement;

7. Operating system: equipped with car color touch screen and wireless multi-function handheld operation box, convenient human-computer interaction, real-time control of the overall situation, and site setting and path planning through simple operation;

8. Warning system: AGV has sound, light, voice prompt and other alarm functions, can automatically diagnose faults and screen prompt operation, real-time feedback task progress and emergencies, greatly improving the operation efficiency;

9. Power system: the large capacity lead-acid battery is equipped with bright color power display and voice prompt function, which can not only intuitively obtain battery power information, but also greatly facilitate the coordination of single machine use time and effectively protect the battery.

The 3D model designed by Solidworks 2017, the file totally 97 MB.