DC53 is a high-strength and toughness general-purpose cold-working die steel. It is an improved version of SKD11 by Japan Datong Co., Ltd. DC53 completely overcomes the shortcomings of SKD11 high-temperature tempering hardness and toughness. It will completely replace SKD11 in high-precision molds.

After being quenched at 1040 ℃ and tempered at 520 ~ 530 ℃, the hardness of DC53 can reach 62 ~ 63, and the toughness is twice that of Cr12MoV. It is the highest among the commonly used cold work die steels. Good, the residual stress of the electromachined metamorphic layer is small, the residual austenite is very little, and the carbides are fine and evenly distributed. Due to the complexity of mold stress, some mold working parts need to have some special mechanical properties. If the standard heat treatment process often fails to meet the ideal work performance requirements, heat treatment is required to make basic characteristics such as hardness, toughness and wear resistance. Appropriate adjustment to achieve the best working state of the mold. Quenching temperature and tempering temperature are the main process parameters of heat treatment, focusing on the tempering characteristics of DC53.

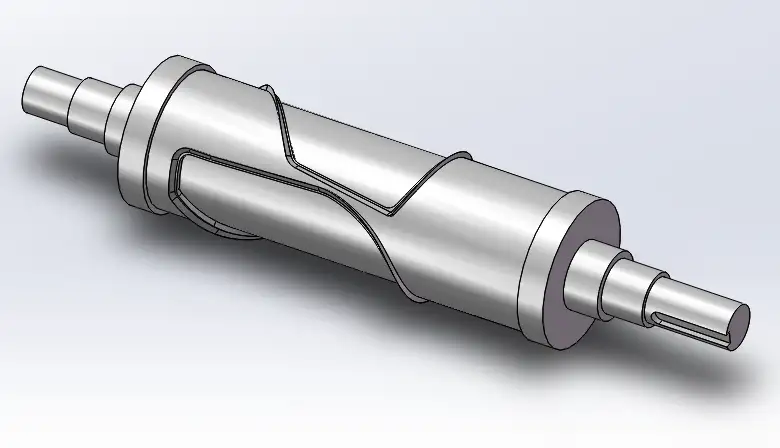

Download the solidworks2017 3D model

KN95 cutting roller 01

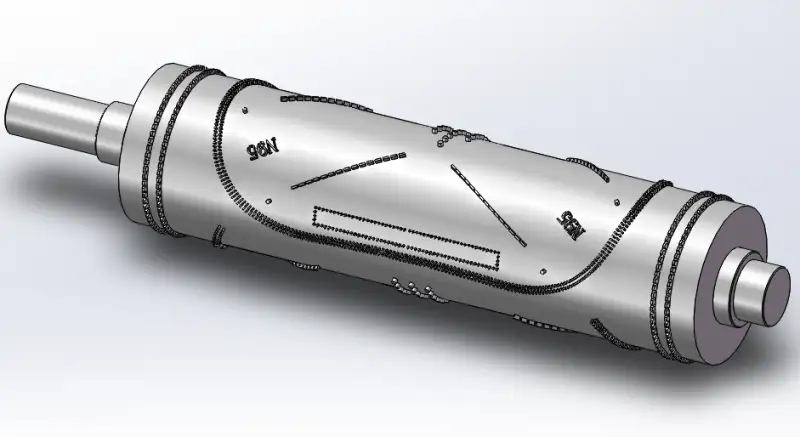

Download the solidworks2017 3D model

KN95 Edge roller 01

In the experiment, some changes were made to the DC53 heat treatment specifications, the quenching temperature was adjusted appropriately, and the tempering temperature was taken at 6 levels, namely 100 ℃, 200 ℃, 300 ℃, 400 ℃, 500 ℃, 600 ℃. 100 ℃ tempering adopts 101-2 type drying oven for heating, and the rest adopts SX-25-12 type box resistance furnace for heating. Two samples are taken for each tempering temperature.