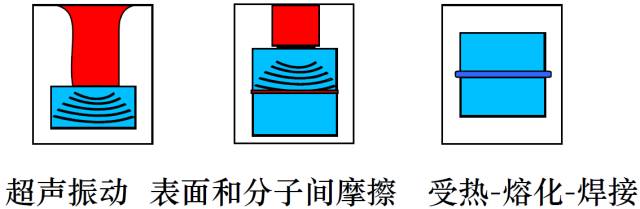

When the ultrasonic wave is applied to the thermoplastic contact surface, it will generate tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration reaches a certain amplitude. The ultrasonic energy is transmitted to the welding area through the upper welding part. The welded interface has a large acoustic resistance, which can cause local high temperatures.

Also, due to the poor thermal conductivity of plastics, they could not be released in time, and gathered in the welding zone, which caused the contact surfaces of the two plastics to melt rapidly. After applying a certain pressure, they were merged into one.

When the ultrasonic wave stops working, let the pressure last for a few seconds to make it solidify and form, so that a strong molecular chain is formed to achieve the purpose of welding, and the welding strength can be close to the strength of the raw material.