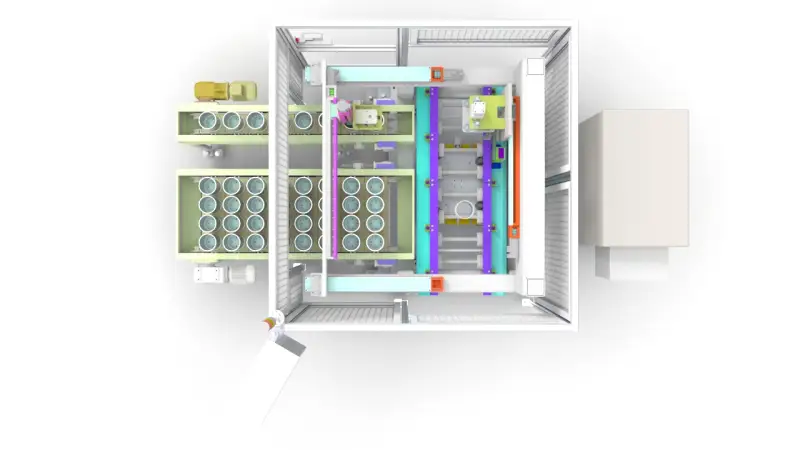

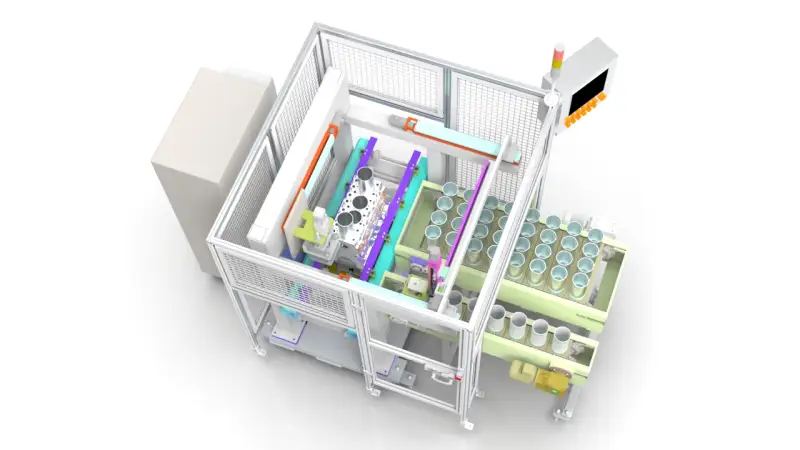

The design of the automated piston cylinder assembly equipment incorporates advanced 3D modeling techniques to streamline the manufacturing process. This equipment is specifically designed to automate the task of piston cylinder installation in engines, ensuring precision and efficiency.

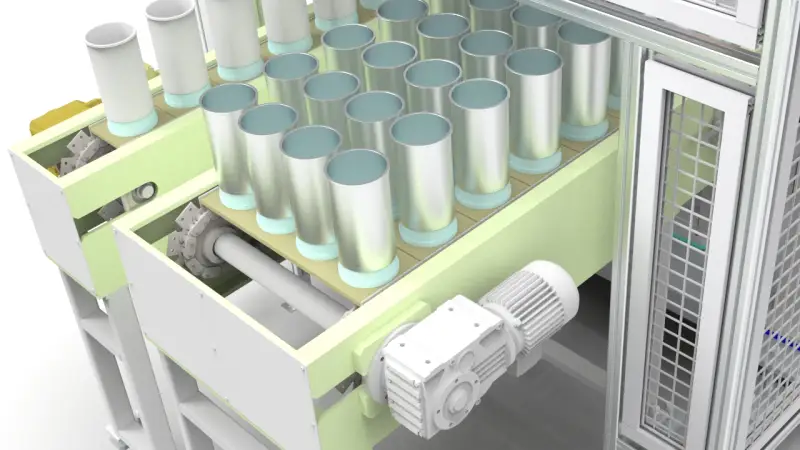

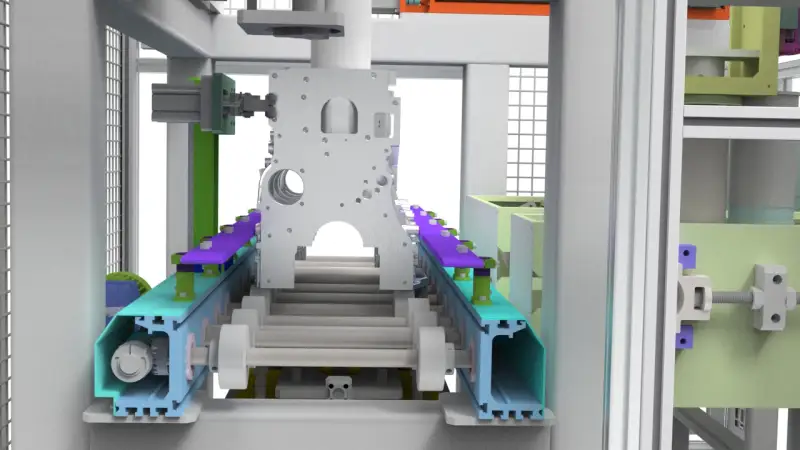

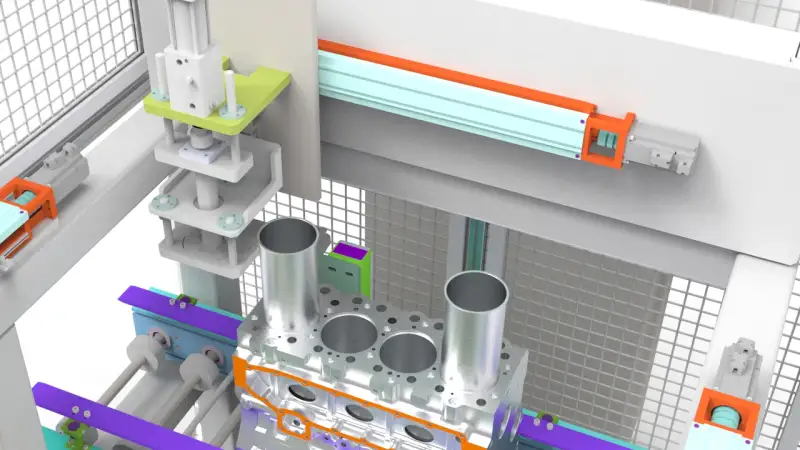

The 3D model showcases a compact and robust structure, equipped with specialized components for precise positioning and secure fastening of the piston cylinders. The design incorporates motorized actuators and sensors for automated movement and feedback control, eliminating the need for manual intervention.

The 3D model accurately represents the various components of the equipment, including the piston cylinder holders, mounting arms, and control panels. It demonstrates the smooth integration of these elements, ensuring ergonomic operation and optimized workflow.

The assembly equipment’s 3D model is created with meticulous attention to detail, capturing precise measurements and tolerances to ensure seamless compatibility with engine specifications. This advanced design provides engineers and manufacturers with a visual representation to assess functionality, identify potential design improvements, and make necessary adjustments before fabrication.

This 3D design was created using SolidWorks 2020. The file size is 391 MB, which includes a step file that can be opened in other 3D software.