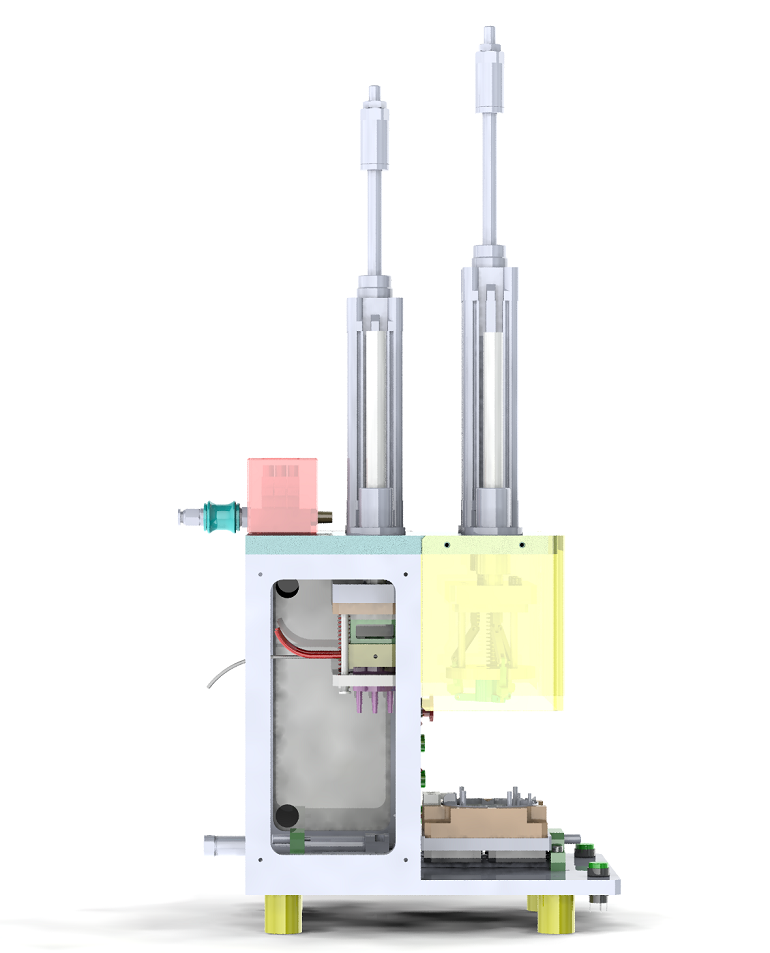

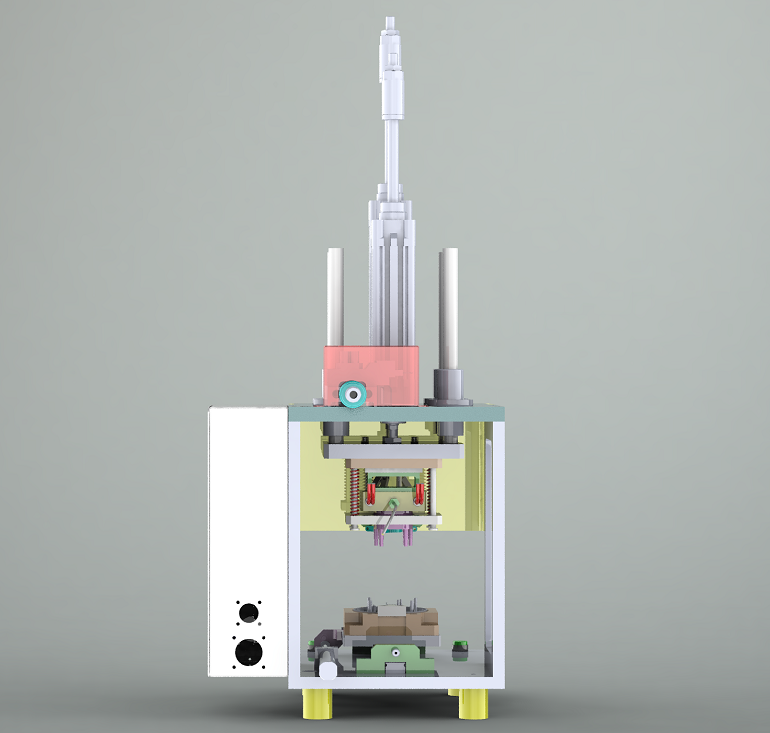

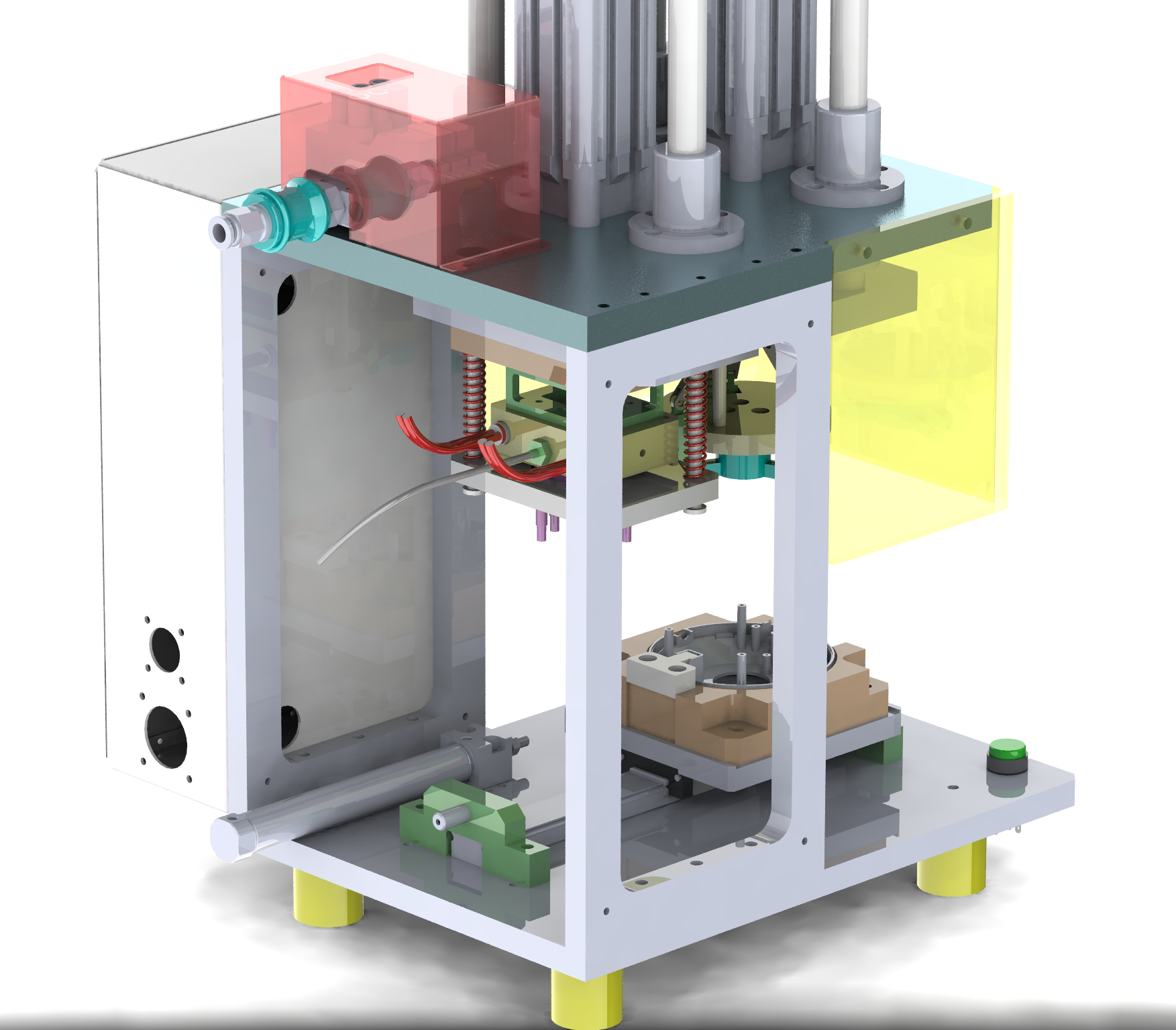

The dual station hot melting riveting press is the perfect solution for manufacturers looking for a reliable and efficient way to join injection-molded parts together. This specialized piece of equipment is ideal for producing high-quality, strong and durable finished products.

Features:

- Two workstations for increased productivity

- Hot melting riveting process ensures a strong bond between parts

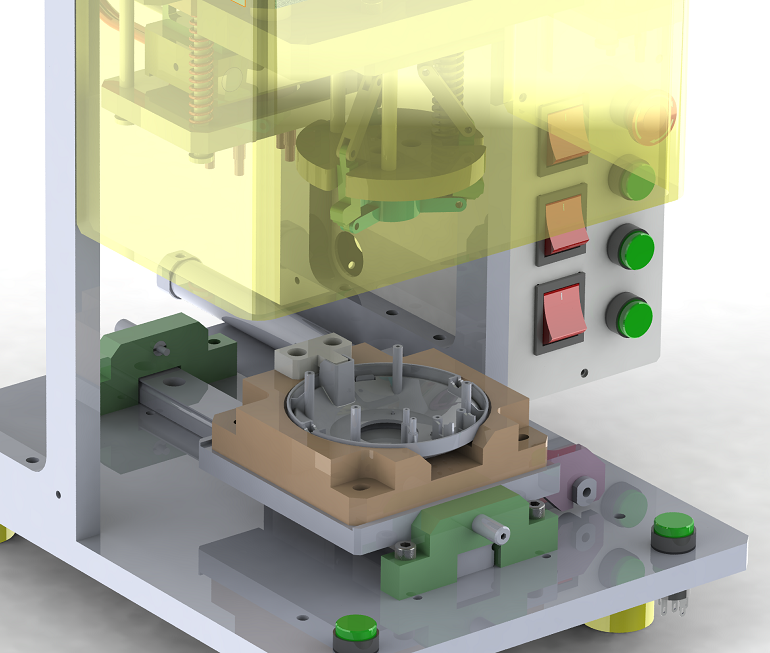

- Precise temperature and pressure control

- Adjustable riveting depth

- Easy to use touch screen control panel

- Fully customizable to suit your specific production needs

Benefits:

- High production efficiency

- Consistent and reliable part-to-part joint quality

- Reduced labor costs

- Increased production yield

- Improved production accuracy

The Dual Station Hot Melting Riveting Press is an innovative and cost-effective solution for manufacturers producing injection-molded parts. With its advanced features and customizable options, this equipment can be tailored to meet your specific production needs.

This 3D model was designed by SolidWorks2017, the file totaling is 46 MB, including step files for other 3D software open.