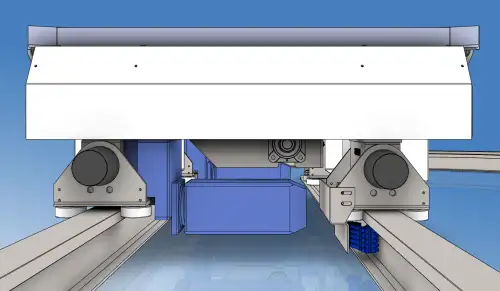

RGV is the English abbreviation for Rail Guided Vehicle, also called rail shuttle. RGV can be used in various high-density storage warehouses. The trolley channel can be designed to be arbitrarily long to increase the storage capacity of the entire warehouse.

And during operation, there is no need for a forklift to drive into the roadway, making it safer. When taking advantage of the forklift not needing to enter the roadway, with the rapid operation of the trolley in the roadway, the operating efficiency of the warehouse is effectively improved.

(Automated Guided Vehicle, abbreviated as AGV), usually also called AGV . It refers to a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can drive along a prescribed guidance path, and has safety protection and various transfer functions.

In industrial applications, there is no need for a driver’s van, which uses a rechargeable battery as its power source. Generally, its travel route and behavior can be controlled by a computer, or an electromagnetic track (electromagnetic path-following system) can be used to set up its travel route. The electromagnetic track is adhered to the floor, and the unmanned vehicle depends on the information brought by the electromagnetic track Move and move.

The concept of AGV and RGV

With the orderly advancement of the national strategic direction of “Made in China 2025”, China’s industrial technology has developed rapidly in recent years, promoting the development of smart manufacturing and smart logistics industries.

As e-commerce logistics, warehousing logistics, factory logistics, and production line logistics are playing a more and more critical role within the enterprise, with the substitution of machines and goods-to-people as the leading idea, modern logistics concepts are deeply rooted in people’s hearts, and logistics warehousing systems are promoting .

There is a common understanding in the development of various industries, and the demand for intelligent equipment in the upgrading of enterprises has gradually become clearer.

The implementation of the automated logistics system and automated warehouse has promoted the development of the enterprise, and RGV (rail shuttle ) and AGV are born because of needs. According to the different working conditions, it can be easily connected with other logistics systems, such as the entry / exit station, various buffer stations, conveyors, elevators and robots, etc., and the materials are transported according to the plan. In addition, it requires no human operation and runs fast.

As a result, the workload of warehouse management personnel is significantly reduced, labor productivity is improved, and the logistics system becomes very simple.